by Qarrem Kassim, Zayana Zaikariah and Fahad Ijlal Nizam

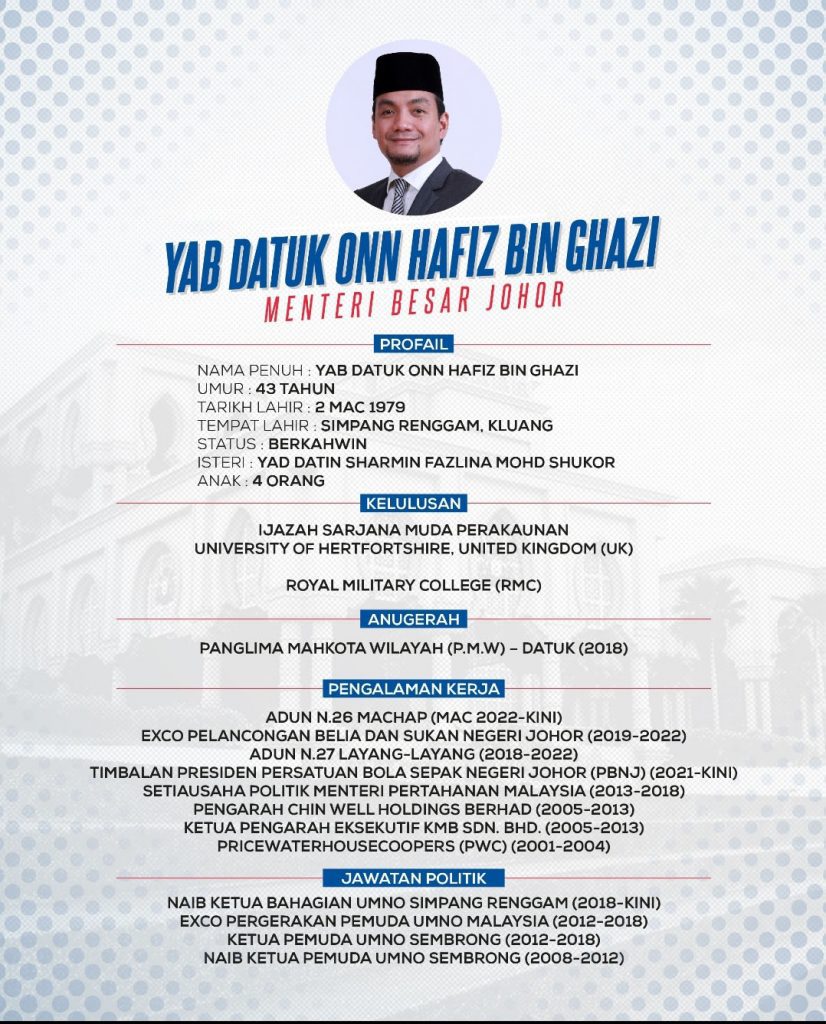

Foreword by Datuk Prof Dr Mohd Faiz Abdullah

October 2025

Key takeaways

- The global race for critical minerals is accelerating. Rare earths, essential for producing high-performance magnets, batteries and defence technologies, now anchor many emerging global supply chains. The US-China geoeconomic rivalry has added additional dimensions of competition, as supply chain bifurcation and export controls actively reshape global mineral supply chains, offering opportunities for Malaysia to broaden its geoeconomic agency.

- Malaysia is endowed with significant deposits of rare earths and is home to one of the world’s largest refineries (i.e., Lynas Rare Earths, Ltd.), yet local industrial integration remains constrained by various governance bottlenecks, a lack of upstream integration and an underdeveloped downstream industrial base. Successfully navigating these challenges and integrating a full-cycle supply chain could unlock an estimated RM91.9 billion in GDP contribution and 96,900 jobs by 2050. (See Appendix II for more details)

- Challenges in the sector include a fragmented governance structure between the federal and state levels of government, resulting in non-optimal coordination and uncertainties that discourage sector investment. The lack of a robust upstream supply ecosystem likewise discourages mid- and downstream development of refining and magnet fabrication capacity, impacting its ability to secure higher value-added stages in the value chain. Lastly, funding for geological mapping and exploration is needed to further drive the sector.

- To overcome these challenges, Malaysia must establish a coherent and integrated governance architecture to guide sector development, such as deepening the institutionalisation of the Special Task Force for the Development of the Rare Earths Industry by creating an advisory and industrial coordination body, while aligning with state agencies. Operators should likewise be tied to compliance audits to maintain regulatory certainty, efficacy and investor confidence. In parallel, a circular economy framework for residue management would enhance material recovery and create additional pathways for sustainable industrial linkages.

- Further, a clear upstream-to-downstream strategy must drive end-to-end manufacturing. This entails creating formal pathways for venture capital and exploration funding, expanding global research and technical cooperation through a unified centre of excellence and localising supply chains for critical chemical inputs. Vertical and horizontal integration must remain a priority, and sustainable mining methods must be incentivised through partnerships with global firms and institutions. SME “plug-in” programmes should likewise be considered to promote inclusive growth across the supply chain.

- Lastly, there is a need to embed ESG, social trust and sustainability principles as a central pillar of sector development. Inculcating the principles of free, prior and informed consent in community engagement is crucial to prevent and protect sector legitimacy, while a robust traceability framework is needed to verify the provenance of materials and ensure alignment with global standards and best practices.