MANY, if not most, workers in the world believe that globalisation and free trade hurt jobs and reduce incomes. It has not helped that great figures of authority, even intellectual giants, hold these views, some as a matter of ideology and others as a matter of perceived fact.

The simple logic seems inescapable: more imports mean fewer opportunities for work for locals. It is also dead wrong. The one thing that has replaced far more workers, contributing to the phenomena of jobless growth, is technology.

It has been estimated by Ball State University researchers, for example, that 85 per cent of the jobs lost in the United States between 2000 and 2010 was due to adoption and advances in automation.

The argument that most American jobs have been exported, not least to Mexico and China, through offshoring and outsourcing flies in the face of the hard evidence.

Closer to home, an International Labour Organisation study last year found that more than half — 56 per cent to be exact — of the labour forces of five Asean countries have a high risk of being displaced over the next 20 years.

The countries were Indonesia, the Philippines, Vietnam, Thailand and Cambodia, which together account for 80 per cent of the region’s workforce or 137 million people.

Textiles, clothing and footwear are especially susceptible, with possible losses of between 60 and 90 per cent of industry job losses. In Cambodia, for example, up to half a million sewing machine operators may lose their jobs. Estimates for the automotive and auto parts industry are 60 to 70 per cent.

Nor are industries susceptible to job losses confined to manufacturing. They include hotels and restaurants, wholesale and retail trade, and construction.

For Thailand, one million shop sales assistants face being replaced by automation, while in Indonesia, 1.7 million office clerks are vulnerable.

Not surprisingly, less educated workers and employees earning lower wages face higher automation risk. Women are also more likely to be displaced.

About the only areas that are at low risk of labour replacement are education and training, health services and social work.

The threats emerging from automation and robotics, especially the highly intelligent variety that is taking their place on factory, office and departmental floors, are not highly noticeable.

We know that the countries that employ the most robots are South Korea (437 per 10,000 workers), Japan (323), Germany (282) and the US (152).

China is expected to have the most number of robots in operation by this year. Its “Made in China 2025” initiative to upgrade its industry to 4.0 standards means that it will not let up any time soon.

What should Asean economies and Malaysia do, or not do, in the face of these trends?

First, launching tirades against globalisation and free trade is misplaced. Raising protectionism levels is going to be undermined by hugely falling unit costs.

All that will be accomplished by preventing integration is to add to transaction costs, open more avenues for rent-seeking and add to marginalisation risks as other economies move ahead.

Second, it is pointless to try and hold back the onset of technology, much as the Luddites did in 19th-century Britain when they set about destroying textile- weaving machinery to preserve their jobs.

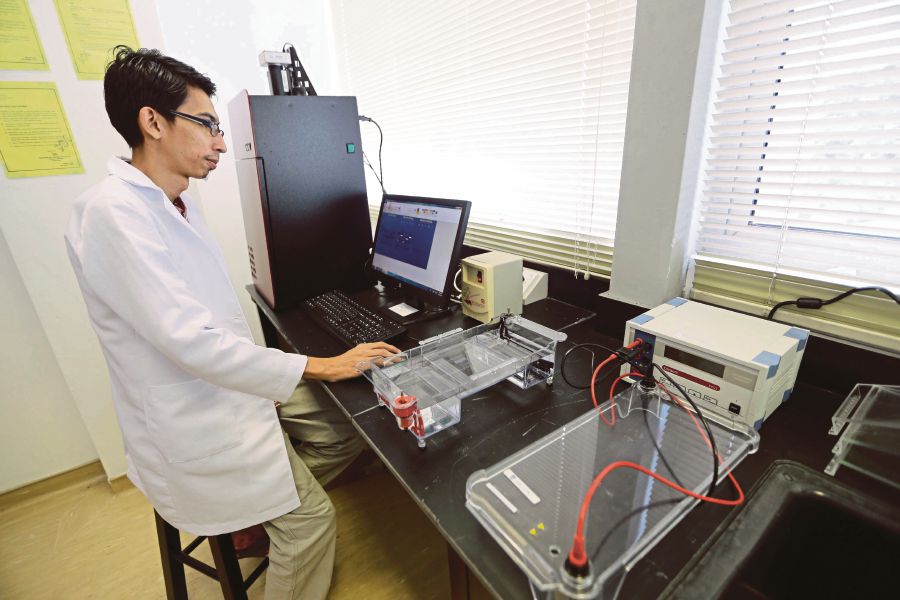

The only answer to technology is to embrace it by adopting, adapting and, hopefully, creating it. Adaptation and localisation are important to avoid going into head-to-head competition with global manufacturers.

Third, the only real security to meeting the challenges of automation is to prep not only our education systems but also our value and belief systems and our thinking systems.

Our future hinges on individual competencies and capabilities. Of this, the greatest will undoubtedly be the ability to self-learn.

More than half of the skills that will be needed in the coming years are not taught today and may not even be taught by educational institutions. It will have to be self-learned.

This article first appeared in The New Straits Times on 23 May 2017.